Chapter 18. Feed Milling Processes

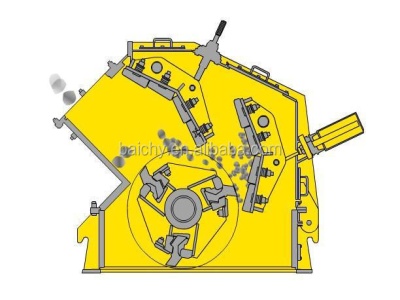

The mill consists of a rotating shaft with four attached parallel knives and a screen occupying one fourth of the 360 degree rotation. The mill is best used to crack whole grains with a minimum of "fines". It is not used as a final process for reducing the size of .