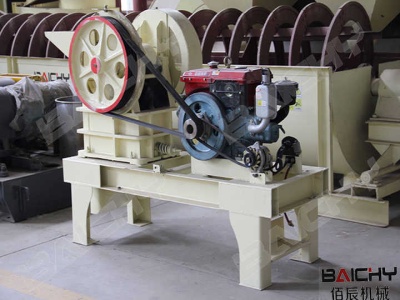

Roller Crusher | Single/Double Roll Crushers

The crusher machine uses two opposite rotating rollers to crush the material. It is composed of an electric motor, support, a fixed roller, a movable roller, a safety spring, etc. With smooth and serrated surfaces. The bearings of the active rollers can move along the frame which supported by strong safety springs.