Maintenance Schedule For Cone Crusher | Crusher Mills, Cone .

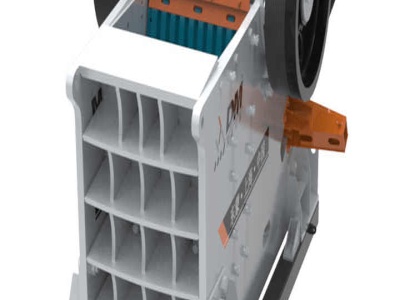

Please feel free to give your inquiry in the form below. We will reply you with details ASAP. ... maintenance schedule for jaw crusher . jaw crusher maintenance schedule – Crusher South Africa. High River Gold Mines Ltd. – Tue Jul 31, 2012 – TaparkoBouroum Hard ore is crushed using a conventional jaw crusher and two cone crushers, while soft ore is sent . JAW .