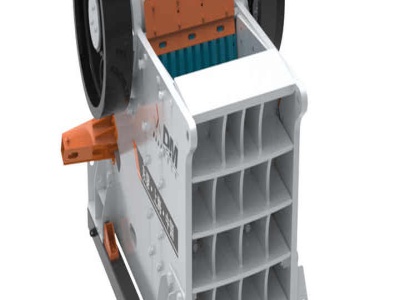

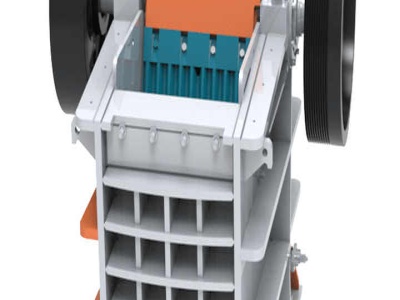

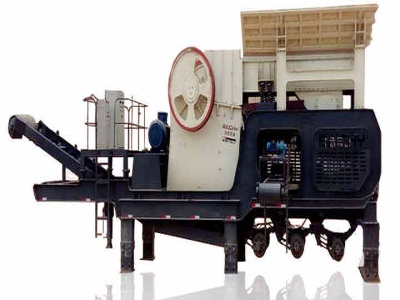

DAGONGMEGA CERAMIC MACHINERY

DAGONGMEGA CERAMIC MACHINERY, the company controlled by MEGA CERAMIC DAGONG MACHINERY, focuses on ceramic raw material processing and equipment researching .From grinding media(alumina ball)to ball mill, from magnetic separator to spray drier, DAGONGMEGA successfully integrates ceramic raw material processing system to provide .