Ore Processing | OceanaGold

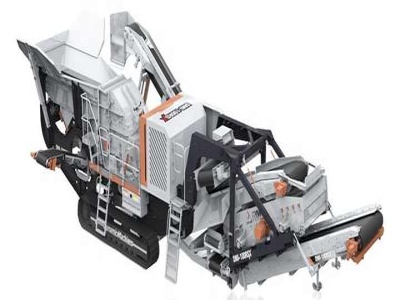

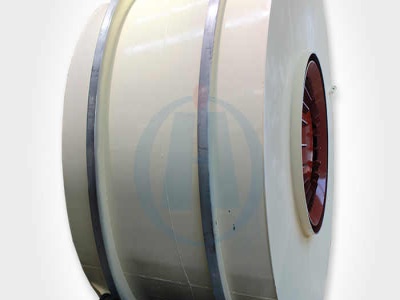

Grinding and Sizing. Ore processing is a 24 hour operation. Ore is stockpiled at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added to raise its pH. Following crushing through a jaw crusher, the ore is fed into the semi autogenous grinding (SAG) mill along with ...

![[mekanism] chemical washers not draining completely, clogging ore ...](/rntgsh3/100.jpg)

![[mekanism] chemical washers not draining completely, clogging ore ...](/rntgsh3/958.jpg)