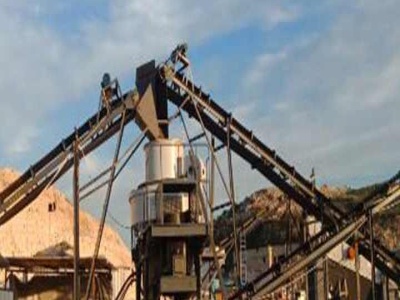

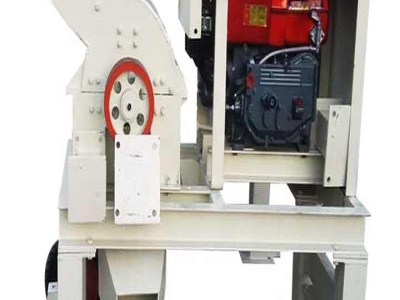

single line diagram coal handling plant

Coal and Coal Products Analytical Characterization Techniques... coal beneficiation. Automated online analytical instruments are key ... industry in the United States for approximately one hundred years. ... Simplified diagram of a modern coal preparation plant. 900 c ο ... handling problems are minimized. More details » Get Price