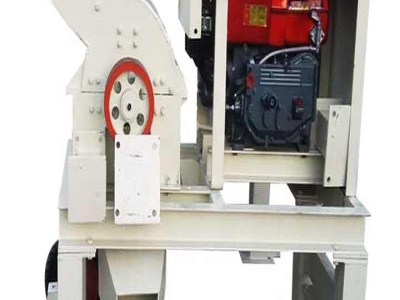

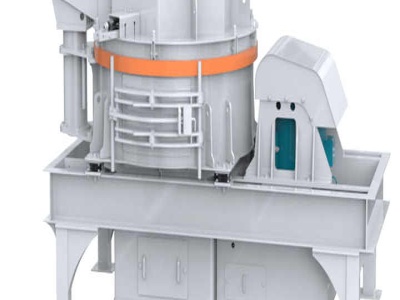

operating characteristics of aggregate crushing equipment

Construction aggregate Wikipedia Construction aggregate or simply aggregate is a broad egory of coarse particulate Large stone quarry and sand and gravel operations exist near virtually all equipment belt conveyors and machines specifically designed for crushing The material being recycled is usually highly variable in quality and properti