Grinding Circuit Final Grind Control at Agnico Eagle Meadowbank .

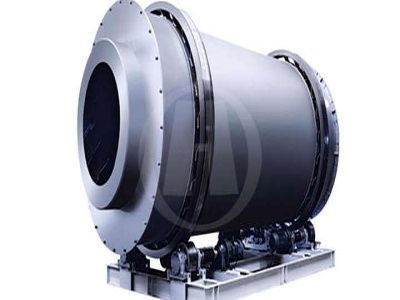

size depending on the required mill feed rate and ore hardness. Figure 3 – Meadowbank milling flowsheet . Crushed ore is conveyed to a covered stockpile with an 8,500 t live capacity. Two variable frequency drive pron feeders reclaima the stockpiled material to a conveyer belt feeding the SAG mill in the primary grinding circuit.