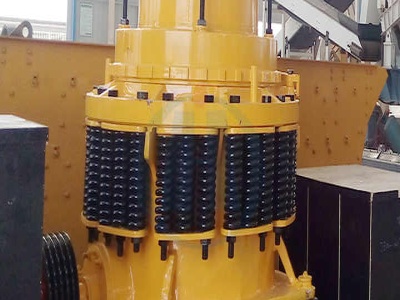

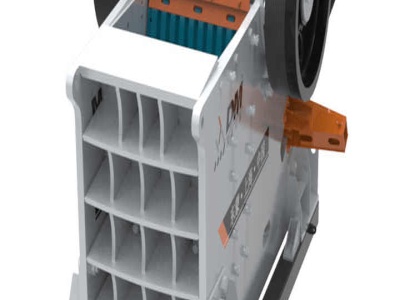

Grinding Efficiency In Ball Mill | Crusher Mills, Cone Crusher, Jaw ...

What is grinding efficiency? Energysaving Ball The grinding efficiency means the consumption 1 kw when . High grinding efficiency ball mill for cement plant | Mobile . High grinding efficiency ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. The ball mill may operate in either . Ball Mills : United .