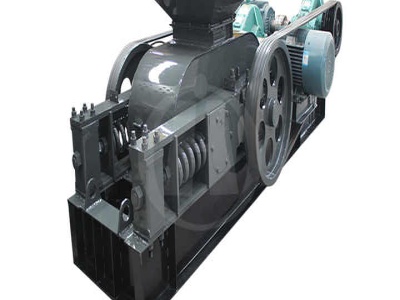

coal mining process flow grinding mill china

mills for gold mining gold mine mill flow chart Coal processing system Machine Energy Review on the AER's home page [•], in HTML and PDF Coal Cleaning US EPA Coal Cleaning Process Description12,9 Coal cleaning is a process by which impurities such as sulfur, ash, and rock are removed from coal to upgrade its value.